Your Guide to Green Precious Metal Recovery

Did you know that more than $60 billion worth of precious metals are discarded each year in electronic waste alone? This staggering figure underlines the critical role of precious metal recycling. Recycling these metals benefits both the economy and the planet. Reclaiming gold, silver, platinum, and palladium helps lower pollution and preserve what’s left of our natural resources.

Firms like Dongsheng Metal Trading spearhead the movement toward greener recycling. They ensure these valuable metals are reused, not dumped in landfills. That precious metal recycler strategy underpins green recycling and long-term sustainability.

Essential Conclusions

- Over $60 billion in precious metals is disposed of in electronic waste annually.

- Recovering these metals cuts eco-impact and preserves resources.

- Valuable metals include gold, silver, platinum, and palladium.

- Green recycling methods are essential for a sustainable future.

- Companies like Dongsheng Metal Trading specialize in metal recycling.

What Makes Precious Metals So Valuable

Precious metals are rare, naturally occurring metallic elements that have captured the interest of investors and industries alike. Gold, silver, platinum, and palladium stand out for their distinct qualities. These include electrical conductivity, corrosion resistance, and substantial rarity. Given the resource-intensive mining and processing, recycling precious metals is essential.

Intrinsic qualities and demand in the marketplace determine precious metals’ worth. Metal recycling ensures the supply chain remains robust. It lowers the ecological damage from mining. Through exhaustive recycling processes, these metals can be restored to their original state. Such efforts save limited resources and create economic gains.

Precious Metals Explained

Precious metals possess unique characteristics that make them desirable for a variety of applications. Their rarity and intrinsic properties are foundational to their economic significance. For example:

- Au: Prized for its shine and tarnish-proof nature.

- Silver: Celebrated for its adaptability and conductivity.

- Pt: Renowned for strength and catalytic uses.

- Palladium: On the rise in automotive and tech industries.

Benefits of Precious Metal Recycling

Recovering precious metals plays a crucial role in sustainability. It preserves resources and lessens the environmental cost of mining. Here are some benefits:

- Reduction of environmental degradation caused by mining operations.

- Using far less energy than fresh extraction.

- Contribution to a circular economy by reintroducing materials into production cycles.

- Potential for financial gains through the reclaiming of high-value materials.

Impact of Recycling Precious Metals

Recovering metals delivers big eco and financial wins. Highlighting these advantages is key to reducing our ecological footprint. Plus, it spurs economic development and steadiness.

Green Benefits

The environmental benefits of recycling precious metals are significant. When we recover metals from e-waste and scrap, landfill volume drops. That cuts new mining needs and saves resources.

This approach minimizes the harmful effects of mining, such as habitat destruction and pollution. A focus on metal recovery moves us toward real sustainability.

Economic Advantages

The economic benefits of recycling are equally compelling. Recycling precious metals can lower manufacturing costs. This allows industries to use reclaimed metals instead of new ones.

It spawns jobs in recovery plants and steadies markets as recycled-metal demand rises. Harnessing these gains helps firms improve their bottom line. They add to a more sustainable marketplace.

How Precious Metals are Recycled

Metal recycling demands a multi-stage process to optimize recovery. It starts with collecting metals from various sources like discarded electronics, jewelry, and industrial scraps. They are sorted, decontaminated, and analyzed to gauge composition and value.

Recycling Workflow

Such a methodical process ensures efficient recovery. Each step is designed to optimize the yield of precious metals. Sorting separates metals by type and purity. Decontamination eliminates residues that block recovery. Analysis identifies the concentration of precious metals, guiding the choice of recycling techniques.

Recycling Techniques Used

High-tech methods are used to maximize metal retrieval. One method, thermal reduction, leverages heat to separate metals from base materials. Smelting and chemical baths extract and purify metals. Firms such as Dongsheng Metal Trading apply these techniques to raise recovery and profits.

Recyclable Precious Metals

Recycling is vital for the environment and for recovering valuable materials. Numerous precious metals lend themselves to recycling, serving both business and environment. It’s important for people and businesses to know which metals can be recycled.

Key Precious Metals

Familiar precious metals include gold, silver, and platinum. You’ll see them in rings, currency, and industrial parts. Gold recovery is widespread because of its worth and need. Silver recovery matters too, thanks to its role in imaging, tech, and solar.

Platinum, while rarer, finds value in catalytic converters.

E-Waste Metals

Electronic precious metals offer unique recycling chances. Smartphones, laptops, and tablets contain rare metals like palladium and indium. Reclaiming them cuts e-waste and recovers key resources.

It’s crucial to recover these electronic metals. Industries aim to minimize waste and efficiently recycle resources.

Industry Benefits of Precious Metal Recovery

Metal recovery underpins major sectors by supplying reclaimed resources sustainably. The electronics industry, with its frequent use of precious metals in devices, benefits greatly. Aerospace and healthcare rely on them for vital parts. Examining industry recovery uncovers eco- and economic advantages.

Tech Electronics

Electronics spearheads recovery, given the metal content in phones and PCs. Rapid technological advancements have led to a significant increase in electronic waste. This makes effective recycling of these metals, such as gold, silver, and palladium, critical. It not only conserves natural resources but also reduces mining-related carbon emissions.

Firms ramp up recycling to hit sustainability targets. That change bolsters resource saving and ecosafety.

Aerospace & Medical

Aerospace metal recycling is vital for the aerospace and medical industries, which rely on precious metals for critical components. High-performance alloys are essential for manufacturing flight parts and medical devices due to their durability and resistance to corrosion. Recycling these metals can significantly lower material costs and comply with environmental regulations.

They recognize that recycling offsets material scarcity. And it improves operations, making metal recycling a smart green tactic.

Selecting Recycling Partners

Locating reliable recycling partners ensures great results. You should probe their procedures thoroughly. Pricing models and processes make a big difference. By comparing services, you can see what each company offers and make a smart choice.

Questions to Ask Recycling Companies

- Which recovery certifications does your company have?

- How do you process various precious metals?

- What yields can you deliver for gold, silver, and more?

- Can you detail your fees and any surcharges?

- Do you have client testimonials or references?

Comparing Prices and Services

When searching for a recycler, it’s vital to compare different companies based on their services. Use a table to line up these factors:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

Side-by-side comparisons help pinpoint the ideal recycler. This ensures you get the most value and meet industry standards.

Your Metal Recycling Handbook

Grasping recycler workflows is essential for metal recovery. They oversee everything from scrap pickup to refining. This ensures maximum efficiency and value from metals.

Recycler Operations

They apply high-tech processes—testing, sorting, refining—to recover metals. First, they gather scrap from multiple origins. Next, they employ precise methods to sort metals. Finally, they refine each batch to recover gold, silver, platinum, etc.

It optimizes yield while advancing environmental goals. It’s a critical step towards sustainable development.

Finding Your Perfect Recycling Partner

You’ll want to weigh several factors in your choice. First, look at their environmental practices. In today’s market, a commitment to sustainability is essential. Also, consider the services they offer, from basic collection to full processing.

Your budget will influence your choice. Get quotes to compare different options. Firms such as Dongsheng Metal Trading tailor services to each sector. They remain a trusted partner for targeted recovery.

Pick the Right Facility

Recycling centers play a key role in sustainability and waste control. It encompasses various recycling centers, each tailored to specific metal recovery needs. Awareness of facility types guides you to proper recyclers. That supports firms and ecosystems alike.

Types of Facilities Available

Metal recycling facilities vary widely in their operations. Some focus on precious metals, while others handle a wide range of materials. Here are a few common types:

- Scrap yards process a broad mix of metal types.

- High-value metal recyclers provide precision recovery for gold, silver, platinum, etc.

- E-Waste Recycling Centers: Specialize in recovering metals from discarded electronics, capitalizing on the valuable components often found in these devices.

Choosing Facility Locations

Accessibility to recyclers is key for efficient metal recovery. Companies should evaluate haulage considerations. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Distance | Nearby recyclers reduce haul time and expense. |

| Networking | Having established relationships with local recyclers can enhance efficiency in recycling processes. |

| Service Range | Awareness of service menus aids in picking the right center. |

In sum, selecting the right type of recycling center and ensuring convenient access can significantly enhance the efficiency of metal recycling operations.

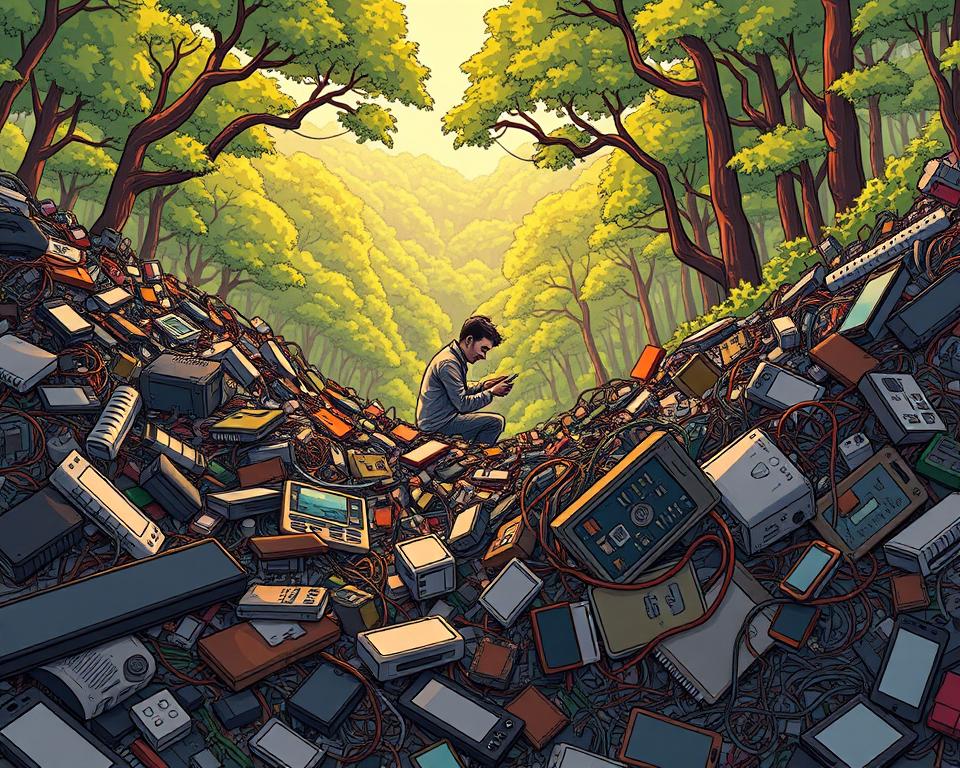

Electronic Waste Recycling and Precious Metals

E-waste poses a major ecological challenge. Many e-waste items hold recoverable precious metals. It shows why we should treat e-waste as treasure.

How Electronics Contain Precious Metals

Devices often contain bits of gold, silver, and palladium. These metals are found in various parts:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

From phones to TVs, electronics pack precious metals. With recycling, we can efficiently recover and reuse them.

E-Waste Recovery Benefits

E-waste recycling is vital for both environmental protection and resource recovery. That cuts landfill volume and conserves resources. Key perks include:

- It lowers pollution risks tied to discarded electronics

- It curbs carbon footprints with sustainable recycling

- It bolsters circular models by returning scrap to production

Promoting e-waste recovery advances resource stewardship. It secures a healthier planet for tomorrow’s children.

What’s Next in Metal Recycling?

The field of precious metal recycling is undergoing a transformation, driven by technological progress and a surge in sustainability efforts. Facing resource limits, recyclers embrace new methods. By integrating novel processes, they pave the way forward.

Eco-Friendly Recycling Innovations

Today’s sustainable recycling prioritizes waste reduction and low impact. Businesses adopt green packaging and energy-saving techniques. Such moves match worldwide green goals and nudge industries to be more eco-responsible.

Cutting-Edge Recovery Methods

Breakthroughs in recovery boost metal recycling yields. Automated sorters and hydrometallurgy ramp up yield. They ramp up yields and shrink eco-footprints, advancing metal recycling.

Starting a Precious Metal Recycling Venture

Starting a precious metal recycling business demands meticulous planning and a deep grasp of operational and market dynamics. Entrepreneurs must outline key steps to build a strong foundation and adhere to industry regulations. Key tasks include market studies and pinpointing customer segments. Securing licenses and legal compliance is crucial for long-term viability.

Business Setup Steps

To launch your recycling venture, follow these steps:

- Analyze market demand and competitor landscape.

- Draft a strategy blueprint covering targets and methods.

- Invest in equipment tailored to your process needs.

- Secure funding through loans or investments.

- Obtain vital permits and licenses for legal operation.

- Deploy promotional plans to gain customers.

Legal Considerations and Certifications

Understanding legal aspects when starting a precious metal recycling business is critical. Adherence to environmental regulations ensures your operation is safe and sustainable. Key considerations include:

- Securing business certification from relevant authorities.

- Ensuring full compliance with disposal and recycling laws.

- Training staff in safety protocols and best practices.

Final Thoughts

Precious metal recycling is essential for preserving natural resources and improving environmental health. It helps people and companies cut waste’s ecological toll. The recovered metals reduce mining needs and boost the economy by creating jobs in recycling.

Recycling goes beyond environmental benefits, also providing economic advantages. Teaming with Dongsheng Metal Trading secures sustainable methods. That partnership bolsters circular models for recyclers and buyers alike.

The journey to a sustainable future depends on collective action in recycling precious metals. Increased awareness builds a culture of green consumption and care. Adopting these practices will benefit us now and secure a greener future for generations to come.