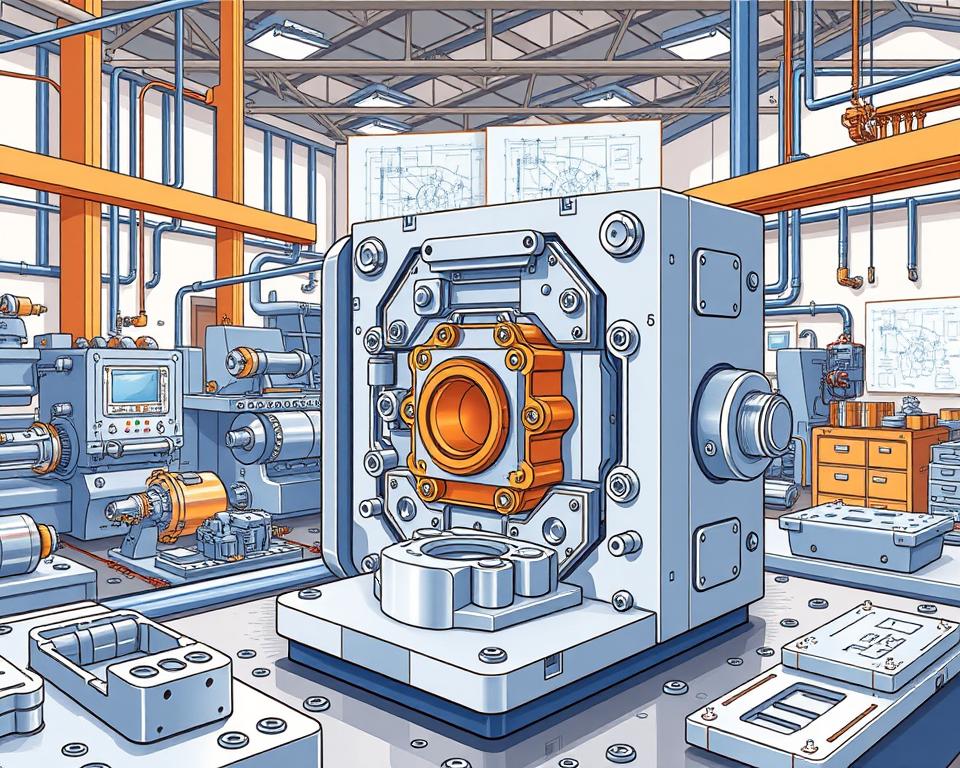

Houston’s Top-Rated Mold Design Services

It’s projected that the global injection molded plastics industry will swell to $440 billion by 2025. This growth underlines the importance of professional mold design services. They deliver bespoke, top-tier mold designs across multiple sectors. Among Houston companies, Lowrance Machine is renowned for mold design. They offer innovative solutions for automotive, aerospace, and consumer products.

Lowrance Machine uses advanced technologies like CAD software and 3D printing. Their specialists deliver efficient, highly precise mold production. With their extensive experience and technical skills, they are a reliable partner for businesses. Discover how their industrial molds Houston offerings improve project outcomes and satisfy current market needs.

Understanding the Importance of Mold Design Services

In manufacturing, mold design services directly influence quality and process efficiency. The role of mold design is immense; it shapes the performance and longevity of products. By prioritizing professional mold design, firms reduce costs and improve quality measures.

Seasoned professionals at Lowrance Machine illustrate the benefits of expertise. They collaborate intimately with customers to engineer bespoke molds. Using advanced CAD and 3D models, they ensure molds meet stringent criteria.

Choosing top-notch mold design services boosts product performance and drives business success. Streamlined mold design fosters efficient production and sharpens competitive stance.

Houston Mold Design: Service Categories

Lowrance Machine offers a wide range of mold design Houston services, tailored to meet specific industry needs. Familiarity with service categories ensures companies pick the right mold solution. Key categories include:

- Custom Design Solutions: Personalized mold design services built around specific demands.

- Test Mold Creation: Early-stage mold prototyping to validate designs.

- Injection Mold Fabrication: High-quality injection molds designed for durability and precision, ideal for various manufacturing applications.

- Advanced 3D Design: Utilization of advanced software to create detailed 3D models of molds, improving design accuracy.

- Mold Repair & Upkeep: Repair and upkeep solutions to maximize mold longevity.

Each service is designed to streamline production, improve product quality, and ensure cost-efficiency. By understanding the available mold services, industries can better meet their manufacturing needs.

Advantages of Expert Mold Design Partners

Engaging professional mold design teams offers significant process improvements. These benefits include enhanced accuracy, durability, and efficiency. Tailored molds ensure top-notch quality and repeatable outcomes.

Seasoned teams provide critical workflow enhancements. They certify molds comply with both generic and custom criteria. This collaboration fosters innovation and improves product lifecycles.

Cost-effectiveness is a significant benefit. Modern techniques curb scrap and shorten lead times. This results in substantial savings, boosting a manufacturing operation’s financial health. Swift design workflows speed time-to-market, sharpening competitive positioning.

Overall, professional mold services underpin manufacturing success. They focus on boosting throughput and product excellence.

Next-Gen Mold Design Innovations

Innovation has driven monumental shifts in mold design. Pioneering these advances, Lowrance Machine adopts the latest techniques. These methods enhance throughput and refine product excellence. Advanced mold design technologies play a significant role, streamlining the creation of unique molds and cutting down on time and costs.

3D printing is a standout among these techniques, enabling quick prototyping and complex designs. It cuts scrap dramatically versus conventional tooling. Simulation platforms enable virtual mold testing and enhancement for superior performance and throughput.

Houston’s mold professionals adopt these forward-thinking approaches. Organizations sharpen their standing by utilizing digital modeling and state-of-the-art fabrication. They support dynamic, client-focused design cycles that address varied sector requirements.

| Technique | Description | Benefits |

|---|---|---|

| 3D Printing | Employs layer-by-layer building for quick mold production. | Reduces lead time and material waste. |

| Simulation Software | Enables digital prototype testing and refinement. | Boosts precision and refines function. |

| CAD Platforms | Integrates advanced software for precise mold specifications. | Facilitates customization and adaptation. |

In Closing

Mold design services are critical for businesses aiming at efficient manufacturing and high-quality production in Houston. These services bring specialized know-how to overcome mold design hurdles. They ensure that each company’s unique needs are met, leading to better outcomes.

Lowrance Machine is a top name in mold design, known for its dedication to precision and collaboration with clients. Bespoke molds and innovative methods from professionals maintain market leadership. Engaging experts boosts standards and refines processes.

Investing in professional mold design in Houston focuses on quality and efficiency. Companies will satisfy market demands and sharpen their competitive edge. Embracing these expert offerings is key to thriving in a challenging marketplace.